ADVANCED TECHNOLOGY AND STATE-OF-THE-ART PROCESSES FOR BOILER TUBING

In 2003, TEKtube, which is now Rosa Operating, added the latest in advanced welding technology - VT 300. At that time, TEKtube was a division of Fintube Technologies, an industry leader and one of the largest users of high-frequency welding equipment in the world. Today, our advanced welding technology is able to significantly improve operational efficiency and production quality in Boiler Tubing.

Our facility incorporates the eddy current test to eliminate worry and build confidence. The eddy current test will provide a higher standard on temperature and atmospheric control. This eddy current test is going to be incorporated after the welding process, as well as after annealing the tube. In addition to that, we will also integrate a heat-treating process, as well.

The Rosa Operating team has many years of combined experience in the tubing industry. When you call Rosa Operating, you are going to get solutions that will assist in quick turnaround, transportation, improved efficiency and reduced costs.

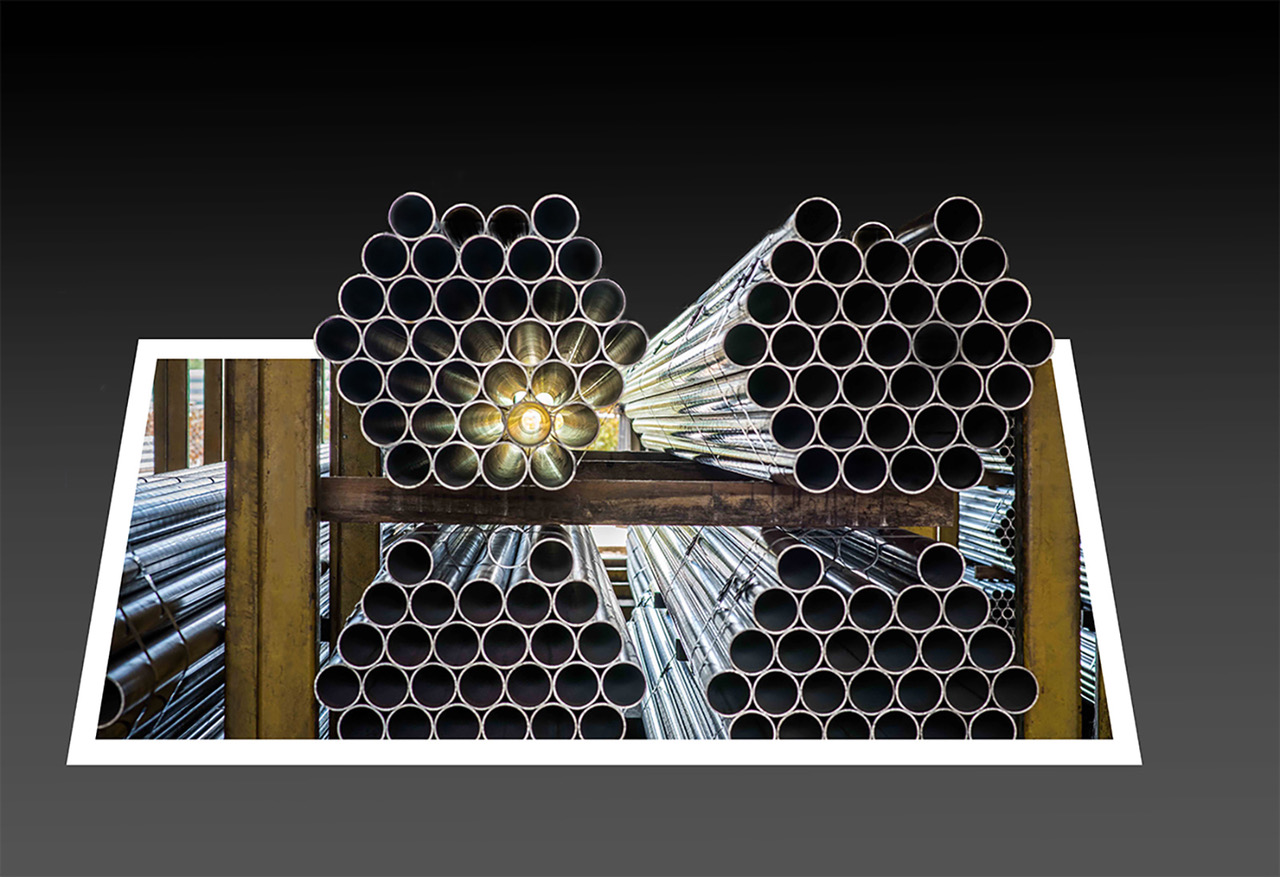

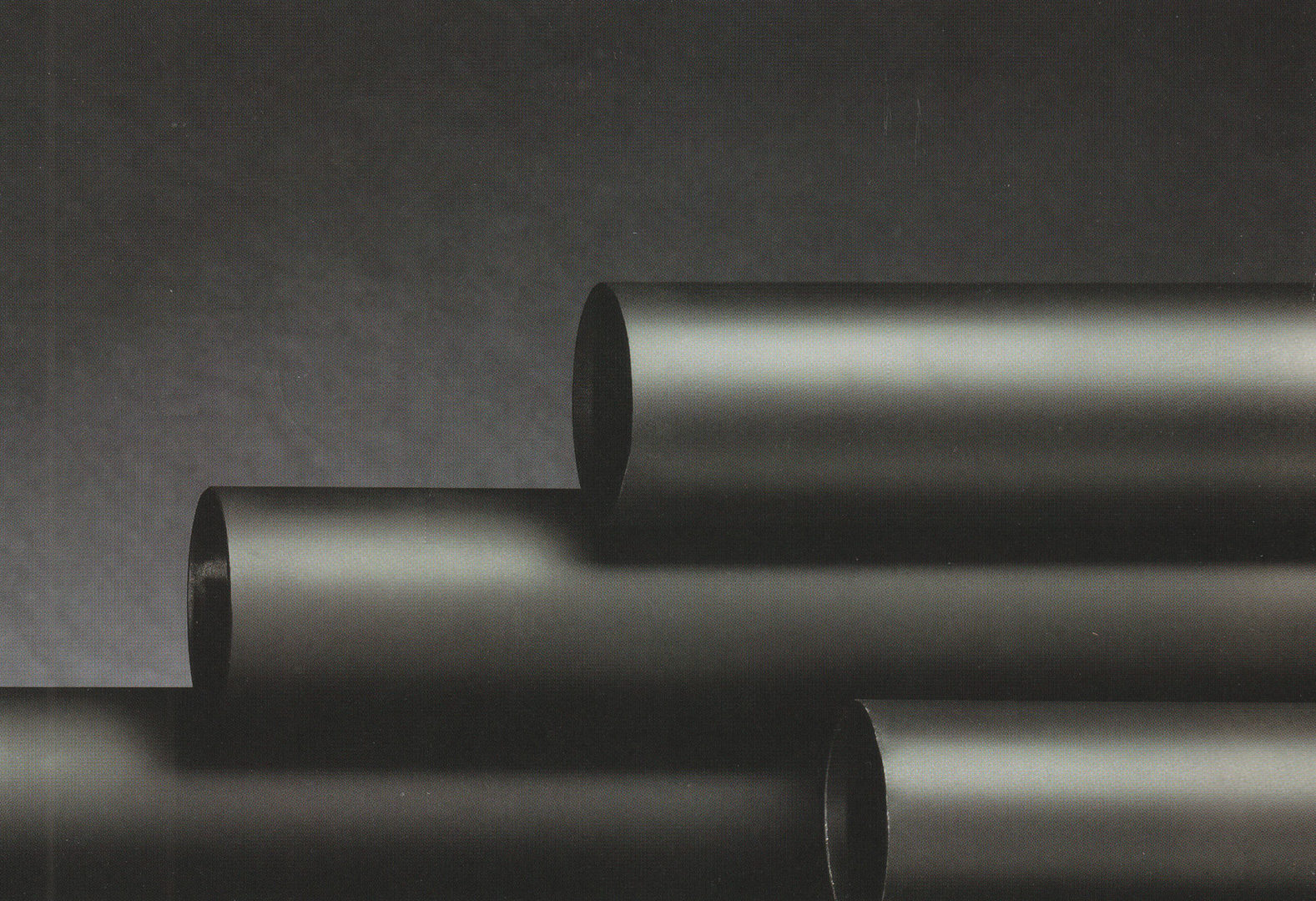

BOILER TUBING

Rosa Operating is a premier manufacturer of electric resistance welded (ERW) Carbon Steel Tubing in North America.

TEKtube’s mill has been successfully manufacturing ERW tubes for heat transfer applications since 1989. Our solid-state high frequency ERW tube mill can produce over 3.5 million pounds of tubing every single month. That is why TEKtube is known as a leading source for major distribution companies in Boiler Tubing.

Advantages of ERW Carbon Steel Tubing

Electric Resistance Welded (ERW) carbon steel tubing offers numerous advantages. With that said, it has become a popular choice among various industries. Here are some of the key advantages:

- High Efficiency: ERW Boiler Tubing can be manufactured in large quantities, particularly with consistency in the dimensions and properties. The automated nature of the production process is going to ensure high efficiency, as well as reduce the likelihood of defects.

- Good Dimensional Accuracy: Electric resistance welded tubes are manufactured to have tight tolerances and precise dimensions. For this reason, they are especially ideal for applications that require strict size specifications.

- Versatility: ERW carbon steel tubing can be used in a wide range of applications - such as construction, power generation, steam production and heat production. ERW tubes are available in various shapes, sizes and grades, in order to meet specific requirements.

- Strength and Durability: Carbon steel is widely known for its strength and durability. ERW tubes, essentially, inherit these characteristics. This tubing has the ability to withstand high pressures, making it suitable for applications in industries that require the transportation of fluids or gasses.

- Weld Consistency: The electric resistance welding process will, ultimately, result in consistent and uniform welds along the tube. This will enhance the structural integrity and reliability of the tubing.

- Smooth Surface Finish: ERW tubes are going to, typically, have a smooth surface finish. A smooth surface finish makes them favorable within the tubing industry.

- Environmentally Friendly: Electric resistance welded tubing is technically considered to be more environmentally friendly, especially when compared to other alternatives. This is because steel is known as one of the most recyclable materials. With ERW tubes being made of carbon steel, they can be recycled and ensure minimal environmental impact.

WE SUPPLY BOILER TUBES TO SEVERAL DIFFERENT MARKETS

We always come through for our customers, especially when quality and lead times are critical. Because of that, Rosa Operating has earned the trust of many professionals across a wide range of industries. Our facility can provide Boiler Tubing and heat-recovery products for a variety of applications in several different markets. For instance:

- Power Generation

- Oil & Gas

- Pulp & Paper

- Chemical

- Steel

- Waste Heat Recovery

- Construction

- Pharmaceutical

- Food Production